Understanding Industrial Desiccant Dehumidifiers

In the ever-evolving landscape of business, maintaining optimal environmental conditions is crucial. One prominent solution that has gained recognition in various industries is the industrial desiccant dehumidifier. This article delves into understanding these units, their importance, functionality, and applications, particularly in fields such as Home & Garden, Home Cleaning, and Home Automation.

What is an Industrial Desiccant Dehumidifier?

An industrial desiccant dehumidifier is a specialized device designed to remove moisture from the air using a desiccant material, which is a hygroscopic substance. Unlike traditional refrigerant dehumidifiers that rely on cooling coils, desiccant systems operate independently of temperature, making them highly effective in environments where low humidity levels are essential.

How Do Industrial Desiccant Dehumidifiers Work?

The operation of a desiccant dehumidifier can be broken down into several key stages:

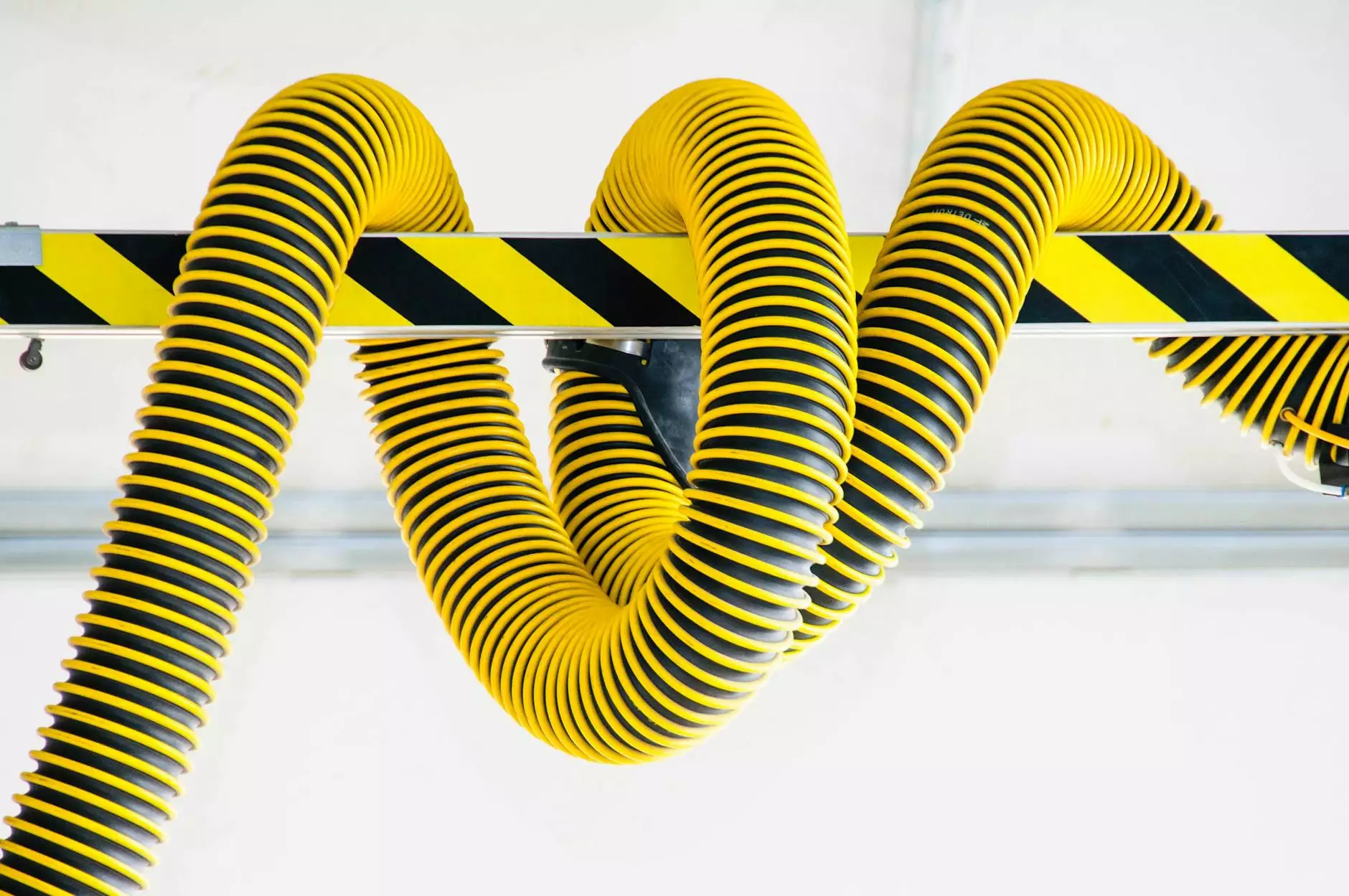

- Air Intake: Moist air is drawn into the dehumidifier.

- Desiccant Absorption: The air passes through a desiccant wheel or material that absorbs moisture from the air.

- Dry Air Output: The moisture-laden air is expelled outside of the unit, while the drier air is recirculated back into the environment.

- Regeneration Cycle: Periodically, the desiccant material is heated to release the absorbed moisture, allowing the cycle to continue.

Benefits of Using Industrial Desiccant Dehumidifiers

The advantages of industrial desiccant dehumidifiers are numerous and can significantly impact operational efficiency and product quality. Here are some key benefits:

- Energy Efficiency: Desiccant dehumidifiers can operate effectively even in low temperatures, reducing energy consumption.

- Low Humidity Control: They excel in maintaining very low humidity levels, crucial for sensitive processes.

- Enhanced Air Quality: By reducing humidity, they mitigate the risk of mold and bacteria growth, promoting a healthier environment.

- Reduced Corrosion: Industries that work with metals, electronic equipment, and delicate instruments benefit from moisture control.

- Versatility: These units are suitable across various industries, from pharmaceuticals to food processing, showing their adaptability.

Applications of Industrial Desiccant Dehumidifiers

The use of industrial desiccant dehumidifiers spans multiple sectors, each with unique requirements for humidity control:

1. Pharmaceuticals

In the pharmaceutical industry, maintaining precise humidity levels is essential to protect sensitive compounds and maintain their efficacy. Desiccant dehumidifiers ensure optimal conditions, thereby safeguarding product integrity.

2. Electronics Manufacturing

Moisture is a significant threat to electronic components. By employing desiccant dehumidifiers, manufacturers can prevent moisture-related failures, ensuring high-quality production standards.

3. Food Processing

The food industry requires stringent moisture control to prevent spoilage and mold growth. Industrial desiccant dehumidifiers aid in achieving the required humidity levels, thereby enhancing shelf life and food safety.

4. Textiles

Textile manufacturing benefits from controlled humidity levels, which affect dyeing and finishing processes. Desiccant systems help maintain the right conditions for consistent product quality.

5. Data Centers

Data centers, which house sensitive electronic hardware, must maintain low humidity levels to prevent condensation. Desiccant dehumidifiers ensure optimal humidity to protect equipment from corrosion and malfunction.

Why Choose Climatronics for Industrial Desiccant Dehumidification?

When it comes to investing in industrial desiccant dehumidifiers, Climatronics stands out as a premier provider in the market. Here’s why:

- Expertise: With years of experience in the field, Climatronics understands the nuances of different industries and tailors solutions accordingly.

- Quality Products: Our products are manufactured using the highest quality standards, ensuring durability and efficiency.

- Customer Support: We pride ourselves on offering exceptional customer service, guiding clients through the entire selection and installation process.

- Customized Solutions: We provide tailored solutions based on individual business requirements, ensuring maximum effectiveness.

- Installation & Maintenance: Our comprehensive services include professional installation and ongoing maintenance to ensure optimal performance.

Key Considerations When Selecting an Industrial Desiccant Dehumidifier

Choosing the right industrial desiccant dehumidifier involves several important factors:

1. Capacity

Evaluate the moisture load of your space to determine the appropriate dehumidifier capacity needed for your operations.

2. Energy Efficiency

Look for units with energy-efficient ratings. Less energy consumption translates to lower operational costs.

3. Maintenance Requirements

Consider the maintenance needs of the system. Units with easy access for service and maintenance will save time and effort in the long run.

4. Application-Specific Features

Some industries may require specific features, such as corrosion resistance or temperature control. Assess your operational needs accordingly.

5. Reviews and Testimonials

Research reviews and testimonials from other businesses in your sector to gain insights into product reliability and company reputation.

Conclusion

In conclusion, industrial desiccant dehumidifiers are an invaluable asset for businesses seeking to control humidity and enhance operational quality. With their robust performance capabilities and versatility across various industries, they address specific moisture-related challenges effectively. Choosing a reputable provider like Climatronics ensures you invest in a solution that meets your unique needs and guarantees superior humidification control.

To explore our range of industrial desiccant dehumidifiers and learn more about how they can benefit your operations, visit Climatronics today!